Surface Rust vs. Deep Rust: Understanding the Differences and How to Treat Them

Rust, the bane of many metal objects, from cars to tools to infrastructure, is a constant battle. But not all rust is created equal. Understanding the difference between surface rust vs. deep rust is crucial for effective treatment and prevention. Identifying the type of rust present allows for targeted solutions, saving time, money, and potentially preventing catastrophic failures. This article provides a comprehensive guide to distinguishing between surface rust and deep rust, exploring the causes, and outlining effective treatment and prevention strategies. Let’s delve into the world of rust and how to combat its various forms.

What is Rust?

Rust, scientifically known as iron oxide, is the result of a chemical reaction called oxidation. This occurs when iron or an iron alloy, like steel, is exposed to oxygen and moisture. The process weakens the metal’s structural integrity, leading to corrosion and eventual disintegration. The rate of rust formation depends on several factors, including humidity, temperature, and the presence of salts or pollutants.

Surface Rust: A Cosmetic Nuisance?

Characteristics of Surface Rust

Surface rust is the initial stage of corrosion, affecting only the outermost layer of the metal. It typically appears as a light, flaky, orange or reddish-brown coating on the surface. Key characteristics include:

- Appearance: Light and powdery, easily brushed off.

- Depth: Limited to the surface, not penetrating deep into the metal.

- Texture: Often feels gritty or slightly rough.

- Impact: Primarily cosmetic, with minimal structural damage in its early stages.

Causes of Surface Rust

Surface rust is commonly caused by:

- Exposure to Humidity: High humidity levels accelerate the oxidation process.

- Minor Scratches and Abrasions: Damaged paint or protective coatings expose the underlying metal.

- Salt Exposure: Road salt and saltwater environments significantly increase rust formation.

- Lack of Protective Coatings: Absence of paint, sealant, or other protective layers.

Treating Surface Rust

Treating surface rust is generally straightforward and can be done with common tools and materials. The goal is to remove the rust and protect the underlying metal from further corrosion.

- Cleaning: Thoroughly clean the affected area with soap and water to remove dirt and debris.

- Rust Removal: Use a wire brush, sandpaper, or a rust remover chemical to eliminate the surface rust. For larger areas, power tools like angle grinders with wire wheel attachments can be effective.

- Surface Preparation: Smooth the surface with fine-grit sandpaper to ensure proper adhesion of protective coatings.

- Protective Coating: Apply a rust-inhibiting primer followed by paint or a protective sealant to prevent future rust formation. [See also: Best Rust Prevention Methods]

Deep Rust: A Serious Threat

Characteristics of Deep Rust

Deep rust, also known as penetrating rust or structural rust, is a more advanced stage of corrosion that extends beyond the surface and into the metal’s core. It poses a significant threat to the structural integrity of the affected object. Key characteristics include:

- Appearance: Darker, often reddish-brown or black, with a pitted or flaking texture.

- Depth: Penetrates deep into the metal, weakening its structure.

- Texture: Rough, uneven, and often accompanied by flaking or crumbling metal.

- Impact: Can cause significant structural damage, leading to potential failure.

Causes of Deep Rust

Deep rust typically results from:

- Prolonged Neglect: Untreated surface rust that has been allowed to progress.

- Severe Exposure: Constant exposure to harsh environments, such as saltwater or industrial pollutants.

- Poor Maintenance: Lack of regular cleaning and protective coating applications.

- Galvanic Corrosion: Corrosion resulting from contact between dissimilar metals in the presence of an electrolyte.

Treating Deep Rust

Treating deep rust is more complex and often requires professional intervention. The goal is to remove the corroded metal and restore the structural integrity of the object.

- Assessment: Thoroughly assess the extent of the damage to determine the appropriate course of action.

- Rust Removal: Use aggressive methods, such as sandblasting, media blasting, or chemical stripping, to remove the deep-seated rust.

- Metal Repair: Depending on the severity of the damage, welding, patching, or metal replacement may be necessary to restore structural integrity. [See also: Metal Repair Techniques for Rust Damage]

- Protective Coating: Apply a high-quality rust-inhibiting primer and protective coating to prevent future corrosion.

Surface Rust vs. Deep Rust: A Side-by-Side Comparison

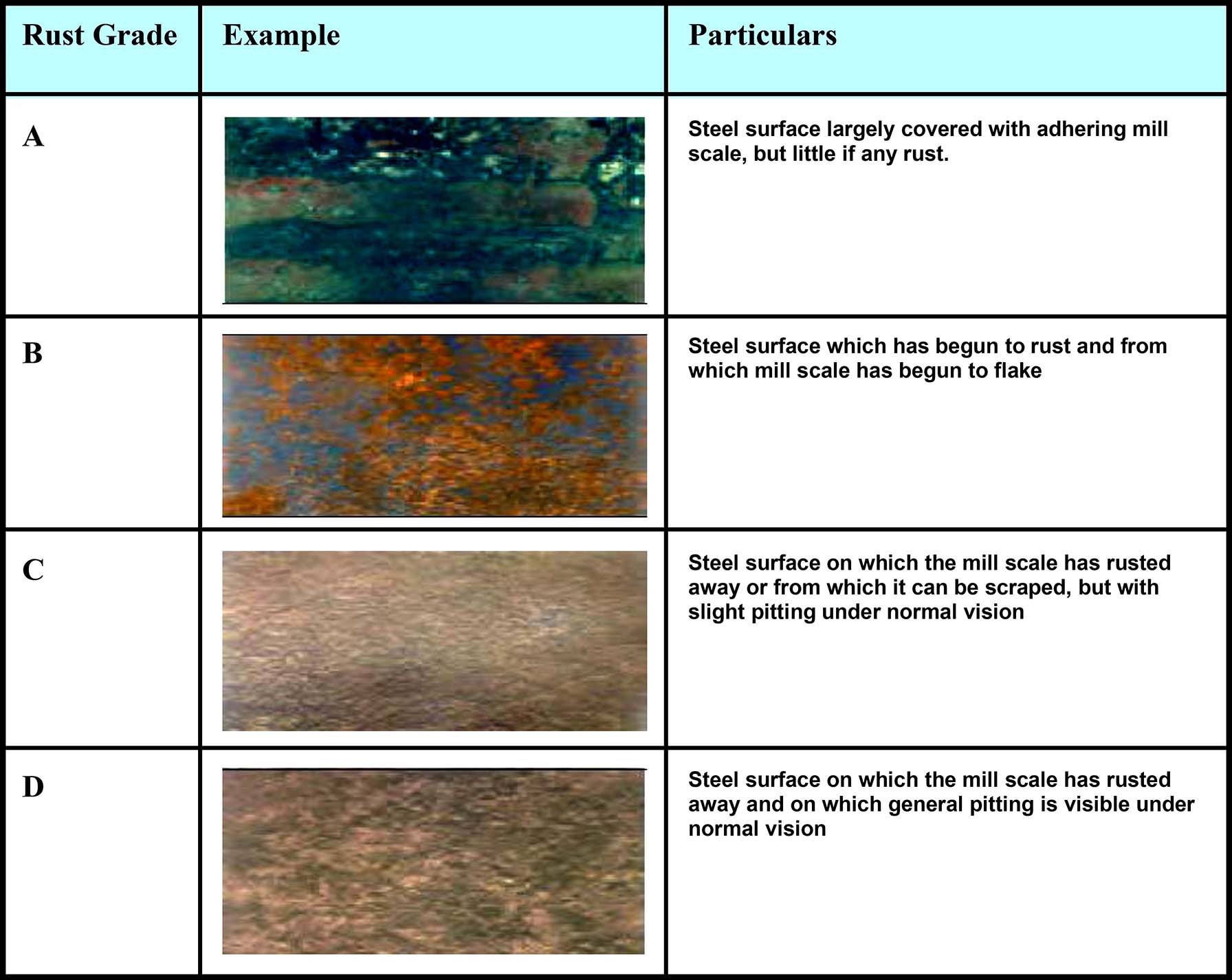

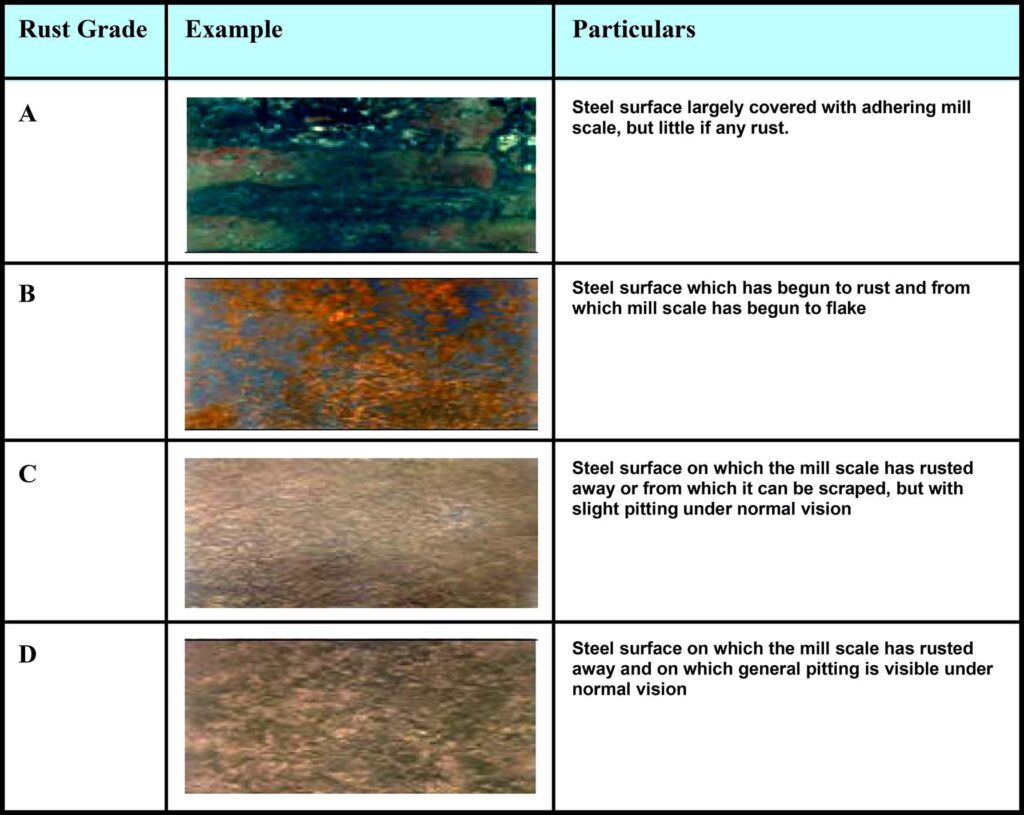

| Feature | Surface Rust | Deep Rust |

|---|---|---|

| Appearance | Light, flaky, orange/reddish-brown | Dark, pitted, reddish-brown/black |

| Depth | Limited to the surface | Penetrates deep into the metal |

| Texture | Gritty, slightly rough | Rough, uneven, flaking |

| Impact | Cosmetic, minimal structural damage | Significant structural damage |

| Treatment | Wire brush, sandpaper, rust remover | Sandblasting, welding, metal replacement |

Preventing Rust: A Proactive Approach

Prevention is always better than cure when it comes to rust. Implementing proactive measures can significantly reduce the risk of both surface rust and deep rust.

- Regular Cleaning: Regularly clean metal surfaces to remove dirt, salt, and other contaminants that can promote rust formation.

- Protective Coatings: Apply protective coatings, such as paint, sealant, or rust-inhibiting sprays, to shield the metal from moisture and oxygen.

- Proper Storage: Store metal objects in dry, well-ventilated areas to minimize exposure to humidity.

- Sacrificial Anodes: Utilize sacrificial anodes (e.g., zinc) in environments prone to corrosion to protect the primary metal structure.

- Regular Inspections: Conduct regular inspections to identify and address surface rust before it progresses to deep rust.

The Economic Impact of Rust

Rust isn’t just an aesthetic issue; it has a significant economic impact. The cost of corrosion, including repairs, replacements, and preventative measures, amounts to billions of dollars annually across various industries. From the automotive sector to infrastructure development, the economic burden of rust is substantial. Addressing rust effectively, by understanding the difference between surface rust and deep rust, is crucial for minimizing these costs.

Real-World Examples of Rust Damage

The consequences of untreated rust can be severe. Bridges, vehicles, and industrial equipment can all suffer catastrophic failures due to corrosion. Consider the example of a bridge with undetected deep rust on its support structures. Over time, the rust weakens the metal, leading to structural instability and potential collapse. Similarly, in the automotive industry, deep rust can compromise the safety of a vehicle by affecting critical components like the frame and suspension. Recognizing the signs of surface rust early and taking appropriate action is vital to prevent these more serious outcomes.

Choosing the Right Rust Treatment Products

The market offers a wide array of rust treatment products, each designed for specific applications. When selecting a product, consider the type and severity of the rust, the type of metal being treated, and the environmental conditions. For surface rust, simple rust converters or inhibitors might suffice. However, for deep rust, more aggressive treatments like chemical strippers or abrasive blasting might be necessary. Always follow the manufacturer’s instructions and take appropriate safety precautions when using rust treatment products. [See also: Rust Treatment Product Reviews]

Conclusion

Distinguishing between surface rust and deep rust is essential for effective rust management. Surface rust, while primarily a cosmetic issue, should not be ignored, as it can progress to deep rust if left untreated. Deep rust, on the other hand, poses a serious threat to structural integrity and requires more intensive treatment. By understanding the characteristics, causes, and treatment options for each type of rust, you can protect your metal assets and prevent costly repairs or replacements. Regular maintenance, protective coatings, and prompt action are key to winning the battle against rust. By adopting a proactive approach, you can ensure the longevity and safety of your metal structures and equipment.