Understanding Bike Brake Lines: Types, Maintenance, and Upgrades

When it comes to cycling safety, few components are as crucial as your bike’s braking system. Central to this system are the brake lines, the unsung heroes responsible for transmitting the force from your brake levers to the calipers, ultimately bringing you to a controlled stop. This article delves into the world of bike brake lines, exploring their types, maintenance requirements, and upgrade options, ensuring you have the knowledge to keep your braking system in top condition.

The Vital Role of Brake Lines

Brake lines are more than just tubes; they are a critical link in your bike’s safety chain. Poorly maintained or inadequate brake lines can lead to delayed braking, reduced stopping power, or even complete brake failure. Understanding how they work and what affects their performance is essential for every cyclist, from casual riders to seasoned professionals.

Types of Bike Brake Lines

Cable-Actuated Brake Lines

Cable-actuated brakes are a common sight on many bicycles. These systems use a steel cable housed within a flexible outer casing to transmit force. The cable runs from the brake lever to the brake caliper. The quality of both the cable and the housing significantly affects braking performance. Over time, cables can stretch, fray, or become contaminated with dirt and grime, leading to reduced responsiveness. The housing can also compress or crack, further diminishing braking efficiency. Regular maintenance, including cleaning, lubrication, and replacement when necessary, is crucial for cable-actuated brake lines.

Hydraulic Brake Lines

Hydraulic brake systems are favored for their superior performance and modulation, particularly in mountain biking and high-performance road cycling. These systems use a fluid, typically mineral oil or DOT fluid, to transmit force from the brake lever to the caliper. The fluid is contained within a sealed brake line, usually made of reinforced rubber or braided stainless steel. Hydraulic brake lines offer several advantages, including consistent performance in varying conditions, less maintenance compared to cable systems (no cable stretch), and superior stopping power. However, they can be more complex to service and may require specialized tools and knowledge.

Rubber Brake Lines

Rubber brake lines are commonly found on entry-level and mid-range bikes. They are relatively inexpensive and offer adequate performance for general riding. However, rubber lines are prone to expansion under pressure, which can lead to a spongy feel at the brake lever and reduced braking power. Over time, rubber can also degrade, becoming brittle and prone to cracking. Regular inspection and replacement are essential to maintain optimal braking performance.

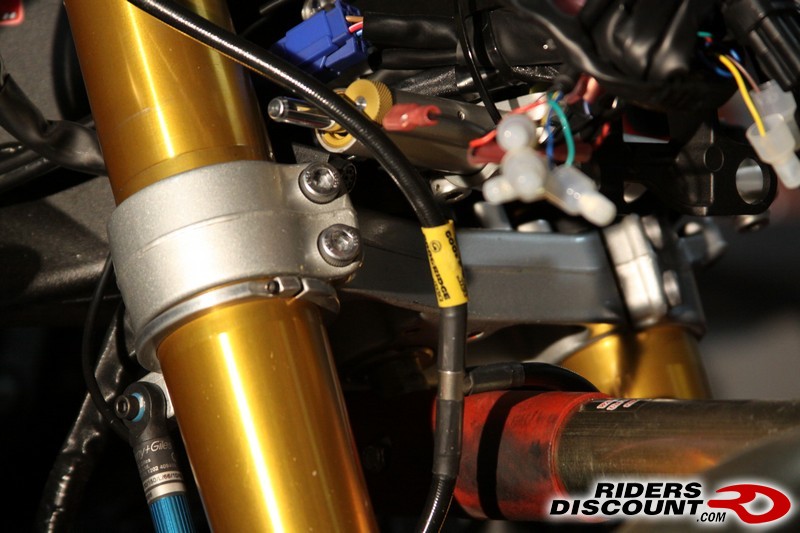

Braided Stainless Steel Brake Lines

Braided stainless steel brake lines are a popular upgrade for cyclists seeking improved braking performance and durability. These lines feature a Teflon or similar inner core surrounded by a braided stainless steel mesh. The stainless steel braid prevents the line from expanding under pressure, resulting in a firmer, more responsive brake feel. Braided lines are also more resistant to abrasion and damage, making them a durable and long-lasting upgrade. While more expensive than rubber lines, the performance benefits often justify the cost for serious cyclists.

Choosing the Right Brake Line

Selecting the appropriate brake line depends on several factors, including your riding style, bike type, and budget. For casual riders and commuters, standard rubber brake lines may suffice, provided they are regularly inspected and maintained. Mountain bikers and performance-oriented road cyclists often benefit from the improved performance and durability of braided stainless steel lines. When upgrading, ensure that the new brake lines are compatible with your existing brake system and that you have the necessary tools and knowledge to install them correctly. If in doubt, consult a qualified bike mechanic. [See also: Bike Maintenance Tips for Beginners]

Maintaining Your Bike Brake Lines

Proper maintenance is essential for ensuring the longevity and performance of your bike brake lines. Regular inspection, cleaning, and lubrication (for cable systems) can prevent premature wear and maintain optimal braking efficiency.

Inspecting Brake Lines

Regularly inspect your brake lines for signs of damage, such as cracks, fraying, or leaks. Pay close attention to the areas where the lines connect to the brake levers and calipers, as these are common points of stress. For hydraulic systems, check for any signs of fluid leakage around the fittings. If you notice any damage, replace the brake lines immediately.

Cleaning Brake Lines

Keep your brake lines clean to prevent the accumulation of dirt and grime, which can degrade performance. For cable systems, use a dry cloth to wipe down the cables and housings regularly. For hydraulic systems, avoid using harsh chemicals or solvents, as these can damage the seals and hoses. A mild soap and water solution is usually sufficient for cleaning hydraulic brake lines.

Lubricating Brake Cables

For cable-actuated brakes, lubrication is essential for smooth and responsive braking. Use a cable lubricant specifically designed for bicycle cables. Apply the lubricant sparingly to the cables, working it into the housing to prevent friction. Avoid using heavy greases or oils, as these can attract dirt and grime. [See also: Best Bicycle Lubricants]

Bleeding Hydraulic Brakes

Hydraulic brake lines require occasional bleeding to remove air bubbles that can compromise braking performance. Bleeding involves opening the bleed ports on the brake levers and calipers and allowing the old fluid to drain out while simultaneously adding fresh fluid. This process requires specialized tools and knowledge, so it is best left to a qualified bike mechanic if you are not comfortable performing it yourself. Air in the hydraulic brake line will cause spongy brake levers and poor braking power.

Upgrading Your Bike Brake Lines

Upgrading your bike brake lines can significantly improve your braking performance and overall riding experience. Whether you are looking for increased stopping power, improved modulation, or enhanced durability, several upgrade options are available.

Switching to Braided Stainless Steel Lines

As mentioned earlier, braided stainless steel brake lines offer a significant performance upgrade over standard rubber lines. The stainless steel braid prevents expansion under pressure, resulting in a firmer, more responsive brake feel. This can be particularly beneficial for riders who demand precise and consistent braking performance.

Using Compressionless Brake Cable Housing

For cable-actuated brakes, upgrading to compressionless brake cable housing can improve braking performance. Compressionless housing is designed to minimize compression under pressure, resulting in a more direct and responsive brake feel. This can be a cost-effective upgrade for riders who want to improve the performance of their cable brakes without switching to hydraulic systems.

Installing Hydraulic Disc Brakes

If you are using rim brakes, upgrading to hydraulic disc brakes can provide a dramatic improvement in braking performance. Hydraulic disc brakes offer superior stopping power, modulation, and consistency in all weather conditions. However, this upgrade typically requires replacing the brake levers, calipers, rotors, and brake lines, so it can be a significant investment. If your bike frame and fork are not disc brake compatible, you will not be able to perform this upgrade.

Troubleshooting Common Brake Line Issues

Even with proper maintenance, bike brake lines can sometimes experience problems. Here are some common issues and how to address them:

Spongy Brake Lever Feel

A spongy brake lever feel is often caused by air in the hydraulic system or expansion in rubber brake lines. Bleeding the brakes can remove air bubbles, while upgrading to braided stainless steel lines can eliminate expansion. For cable brakes, ensure that the cables are properly tensioned and lubricated. [See also: How to Adjust Bike Brakes]

Reduced Braking Power

Reduced braking power can be caused by contaminated brake pads, worn rotors, or problems with the brake lines. Clean or replace the brake pads and rotors as needed. Inspect the brake lines for damage or leaks and replace them if necessary. For cable brakes, ensure that the cables are not stretched or frayed.

Brake Line Leaks

Brake line leaks are a serious issue that can compromise braking performance. If you notice any leaks, replace the affected brake lines immediately. Ensure that all fittings are properly tightened and sealed. For hydraulic systems, use the correct type of fluid recommended by the manufacturer.

Conclusion

Bike brake lines are a critical component of your bicycle’s braking system, and understanding their types, maintenance requirements, and upgrade options is essential for every cyclist. By choosing the right brake lines and maintaining them properly, you can ensure safe and reliable braking performance in all conditions. Regular inspection, cleaning, and lubrication can prevent premature wear and maintain optimal braking efficiency. Whether you are a casual rider or a seasoned professional, investing in high-quality brake lines and keeping them in good condition is a worthwhile investment in your safety and enjoyment of cycling. Consider upgrading to braided stainless steel brake lines for enhanced performance and durability. Remember to consult a qualified bike mechanic if you have any doubts or concerns about your braking system. Prioritizing the maintenance of your brake line bike components will ensure safer and more enjoyable rides.